Direct labor costs may seem to be pretty straightforward; however, these costs don’t just include wages. You want to tally all of the costs that must be paid for the labor needed to actually manufacture a product. Direct labor costs should also include all of the expenses necessary to hire and retain an employee who physically works to turn the raw materials into a product. Manufacturing overheads used in calculating conversion costs are the overheads that cannot be attributed to the production process or a single unit in production, for example, rent or electricity. In some industries, conversion costs, including labour expenses, can exceed the total expenses on raw materials. In the food industry, converting raw food materials into edible food items is labour-intensive and requires specialised machinery.

Period costs are recorded in the profit and loss statement of an organization. One can arrive at total period costs by closely monitoring and reporting the expenses that aren’t related to manufacturing a product. Some costs, notably labor, are included in each, so adding them together would overstate manufacturing cost. As can be seen from the list, the bulk of all conversion cost formula conversion costs are likely to be in the manufacturing overhead classification. Consider a professional furniture builder who is commissioned to build a coffee table for a customer. The primary costs for making the table include both the cost of the furniture maker’s labor and the raw materials needed to build the table, such as lumber, hardware, and paint.

Why Do Companies Have Predetermined Overhead Rates?

For the basic size 5A stick, the packaging department adds material at the beginning of the process. The 5A uses only packaging sleeves as its direct material, while other types may also https://www.bookstime.com/ include nylon, felt, and/or the ingredients for the proprietary handgrip. Direct labor and manufacturing overhead are used to test, weigh, and sound-match the drumsticks into pairs.

- The furniture maker charges $50 per hour for labor, and the project takes three hours to complete.

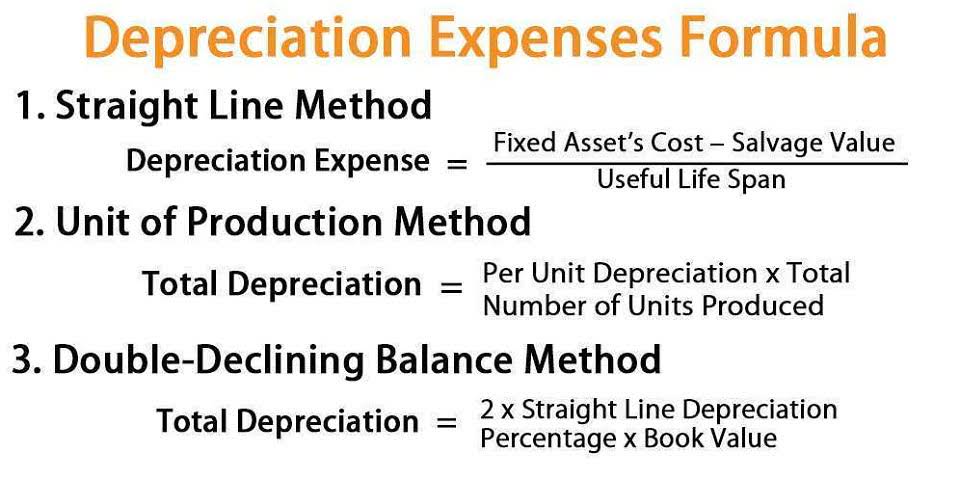

- Conversion Cost includes direct labor and manufacturing overhead, covering all production expenses.

- The conversion cost definition is the direct labor and manufacturing overhead costs needed to convert raw materials into a finished product.

- Managers also use these costs to evaluate the efficiency of the production process and identify waste.

- Conversion costs are the labor and overhead expenses that “convert” raw materials into a completed unit.

- If they were 100% complete with regard to conversion costs, then they would have been transferred to the next department.

Direct labor costs include the salaries, wages, and benefits paid to employees who work on the finished products. Compensation paid to machinists, painters, or welders is common in calculating prime costs. The two components of prime cost formula are direct materials and direct labor.

How to Calculate Goods in Process Inventory

Understanding how conversion costs are calculated and managed is crucial for businesses looking to optimize their operations and drive profitability. By analyzing conversion costs, companies can gain valuable insights into their production expenses and make informed decisions regarding cost reduction strategies. A company’s accounts managers and production managers calculate these conversion costs to estimate the production expenses, and the value of the finished and unfinished inventory, and make product-pricing models. TThese direct labor costs are the same ones used in calculating the prime cost in manufacturing.